How To Identify Metal For Welding!

If you are buying metal or finding metal to weld in a scrap yard it's important you know what you are getting so that know how to weld it properly and if it's weldable.

There are quite a few ways to test metal including using a magnet, doing a spark test, and even chipping it. Some fabricators use pure wisdom; they can identify most material simply by how it looks on the surface including the color.

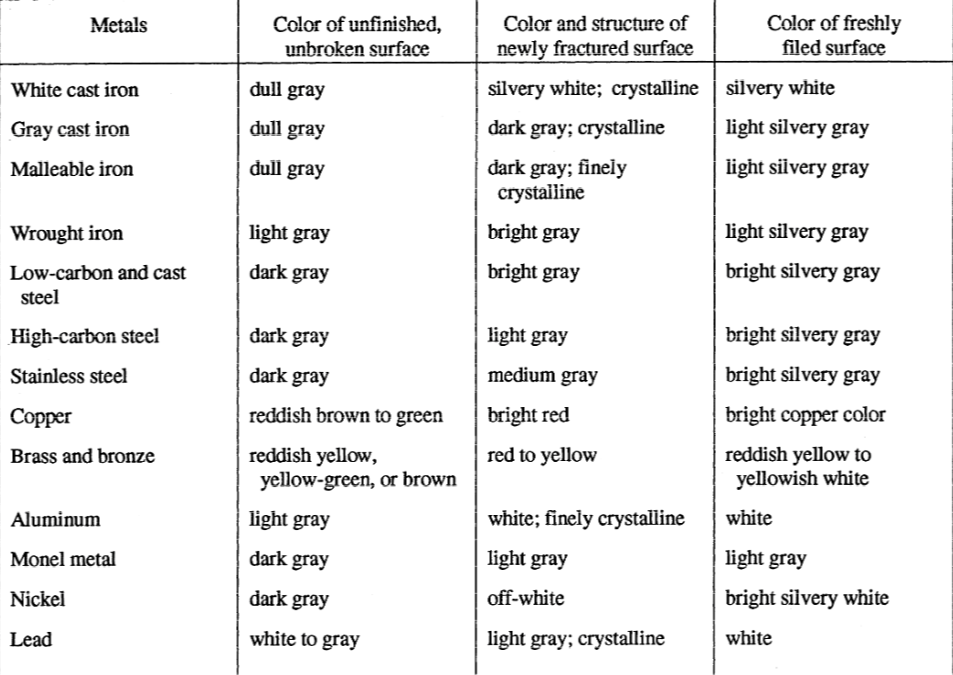

Metal Surface:

Some welders are so good at identifying metal they just need to look at it. This chart (below) provides some insight into how they do it so well. You can figure out what the metal is and it's classification by its color and appearance.

The most commonly used metals in fabrication and what they look like are listed in this chart.

Since looking at a piece of material and feeling it is not always going to reveal it's type, you can also use other identifiers. For example, a piece of metal that has recently been fractured or filed can help you identify it.

- Some of the processes used to make the metal can also give you a clue. For example, a sand mold is used to make most cast iron and you can find some of the mold residue on the cast iron (or malleable iron).

- Forging marks can be found on low carbon steel. You'll find rolling or forging marks on high carbon steel.

- Stainless steel has a fairly rougher appearance than nickel, copper, bronze, wrought iron, and brass. These metals have a smoother appearance.

- Lead on the other hand has a smooth and silky or some say it has a velvet texture.

- Often you'll find material that you cannot identify by simply looking at and feeling it, so you'll need to use other ways of figuring out what the material is.

- Most of us don't have sophisticated equipment to do the testing for us but fortunately there are a few simple and pretty accurate procedures you can do in the field or in your shop, if you know what you are doing and what to look for.

We will look at the most common metal identification tests that don't require high tech equipment.

Spark Test Metal Identification Test!

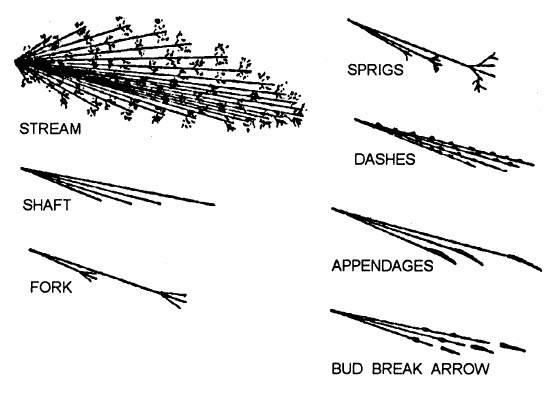

Spark testing terms to help identify the material.

Spark testing terms to help identify the material.A spark test is one of the most common types of tests for identifying material. It's done by holding a piece of metal against a grinding wheel and making it spark (or not). A veteran fabricator can tell what the metal is simply by looking at the type of sparks, or lack thereof.

If you put steel or iron agains an abrasive wheel it will take off tiny bits of metal and because it's done so quickly this material becomes hot.

The small pieces of metal shoot away, glowing, and this is called trajectory, or a 'carrier line'.

To identify the material by the trajectory you'll need to have a dark background to get a good look at it.

A good metalworker can identify the material by looking at how long the spark is, its color, and the sparks shape.

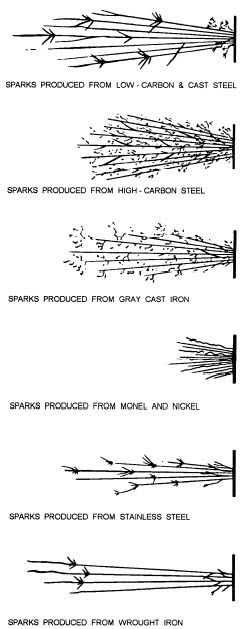

The chart to the right shows you basically what a sparks form and trajectory is based on the material when you do a spark test.

Steel: The trajectory and form of the sparks are effected in different ways by different alloying elements in steels that have the same carbon content which makes it hard to identify the type of steel it is.

An alloying element can vary the speed and color of the spark. For example the spark may be slow or fast, or dark or light depending on what type of element was used in the steel.

For example, an alloying element such as Nickel can make the burst of carbon look like it's being suppressed but the actual spark looks like little bits of white blocks of light. And the alloying element, Silicon, can make the carbon burst even more suppressed than nickel! If silicon is used in the steel the trajectory of the spark has a quick ending with a flash.

- If you take a look at the images just above and to the right of the spark formation based upon the type of material you'll see that low carbon steel (first image) has a spark trajectory which is around seventy inches in length, and the width of it is fairly big.

- High carbon steel (second image down) has a trajectory that is short. It is approximately fifty five inches in length but the width (or volume) is bigger.

If you get some 'sparklers' when spark testing low carbon steel you'll notice that the formation of it is forked. Sparklers that result from testing high carbon steel are smaller but are repeticious.

Both low carbon and high carbon steel has a white colored stream of sparks.

- When testing gray cast iron (third image down) you'll find that the spark stream that is created is approximately twenty five inches. However, the sparklers will be repetitious, and small both in volume and size.

- Also, the spark stream which begins closer to the grinding wheel is reddish and light yellow on the outside part.

With Nickel and Monel material (fourth image down) have very similar spark trajectories. The sparks are going to be orange in color and small in size. You'll get sparks that wave and you'll have no sparklers.

As a result of how similar they are, you'll need to use another testing technique to tell them apart.

- Testing stainless steel (fifth image down) will get you a spark that has a stream that is approximately fifty inches long, medium width or volume, and just a few sparklers, which have a formation that is forked.

The spark stream that is closer to the grinding wheel is light yellowish, and the end of the stream is fairly white in color.

- Wrought iron (sixth image down), has a stream of sparks that are around sixty five inches long. The spark stream is big in volume and very little sparklers are produced. You'll get sparks at the end of the spark stream and they have a forked shape. The sparks near the grinding wheel are light yellowish, but the outside portion of this area is a reddish color and it's quite bright.

Spark Test Tips!

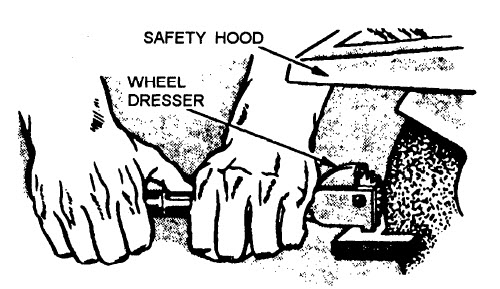

You can accomplish a spark test with just about any kind of grinder at your disposal. But the grinder should have a speed of at least forty five hundred fpm.

The wheel you will use should be pretty rough or coarse. Do not use a dirty wheel and make sure it's a hard one.

The way to produce a spark test is to put the material up against the wheel but make the spark trajectory go to your right or left so that you can get a good line of site on it. Use a dark background for the spark test.

After you do it a few times you'll understand how to position the grinder and or your material to get a good spark.

If you use a lot of pressure you'll fool yourself into thinking you have more carbon in the metal than is actually there because more pressure makes the spark hotter and makes the carbon burst larger as well.

As you do the spark test you'll want to look about 1/3rd of the way from the end of the trajectory of the spark, and only look at the sparks that are going across your line of sight. Visualize and analyze it in your head.

Make sure you follow all the safety guidelines associated with using a grinder. These tools are very handy but they are also very dangerous.

Do you want to get good at spark testing and become the go to guy or gal for identifying material? Then try this:

- Get a bunch of material and do spark tests on it for practice. But when you get bits of material to test make sure they are all around the same size because then you'll know what is what.

- Give each piece of metal a number and match that number to the name of the material.

- Spark test the material but do it without knowing the number of it. Then tell someone else what number it is and see if you matched the right number to the material to test yourself.

- Do this over and over until you get them right all the time and soon you'll be the go to person in the shop or your area for identifying material.

Chip Testing!

A chip test is when you take a little bit of material off of a piece of material you are testing with a chisel. The material you remove can either be small fragmented piece to a strip of material.

The chip you get could result in a smooth texture or have edges that are sharp. It might be a fine grained piece of material or coarse. It's also possible that the material has edges that are like teeth like on a saw.

However the size of the material you chip off is also important.

Metals and Chip Characteristics:

Listed here are all of the common metals you'll be worthing with and what the characteristics are of the chips.

White cast iron:

Chips are small, brittle fragments. Chipped surfaces not smooth.

Gray cast iron:

Chips are about 1/8 inch in length. Metal not easily chipped; therefore, chips break off and prevent smooth cut.

Malleable iron:

Chips vary from 1/4 to 3/8 inch in length (larger than chips from cast iron). Metal is tough and hard to chip.

Wrought iron:

Chips have smooth edges. Metal is easily cut or chipped, and a chip can be made as a continuous strip.

Low carbon and cast steel:

Chips have smooth edges. Metal is easily cut or chipped, and a chip can be taken off as a continuous strip.

High carbon steel:

Chips show a fine-grain structure. Edges of chips are lighter in color than chips of low-carbon steel. Metal is hard, but can be chipped in a continuous strip.

Copper:

Chips are smooth, with sawtooth edges where cut. Metal is easily cut as a continuous strip.

Brass and bronze:

Chips are smooth, with sawtooth edges. These metals are easily cut, but chips are more brittle than chips of copper. Continuous strip is not easily cut.

Aluminum and aluminum alloys:

Chips are smooth, with sawtooth edges. A drip can be cut as continuous strip.

Monel:

Chips have smooth edges. Continuous strip can be cut. Metal chips easily.

Nickel:

Chips have smooth edges. Continuous strip can be cut. Metal chips easily.

Lead:

Chips of any shape may be obtained because the metal is so soft that it can be cut with a knife.

Magnetic Testing!

Perhaps the most commonly uses method for testing metal for a variety of reasons is the magnet test.

See, ferrous metal are alloys with an iron base and they are usually magnetic. Nonferrous metal is not magnetic.

Using a magnet is not one hundred percent accurate due to the fact that there are some stainless steel that is not magnetic. So what do you do? Experience will be your best ally.

Related Articles:

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: