Parts Of A Weld

Diagram:

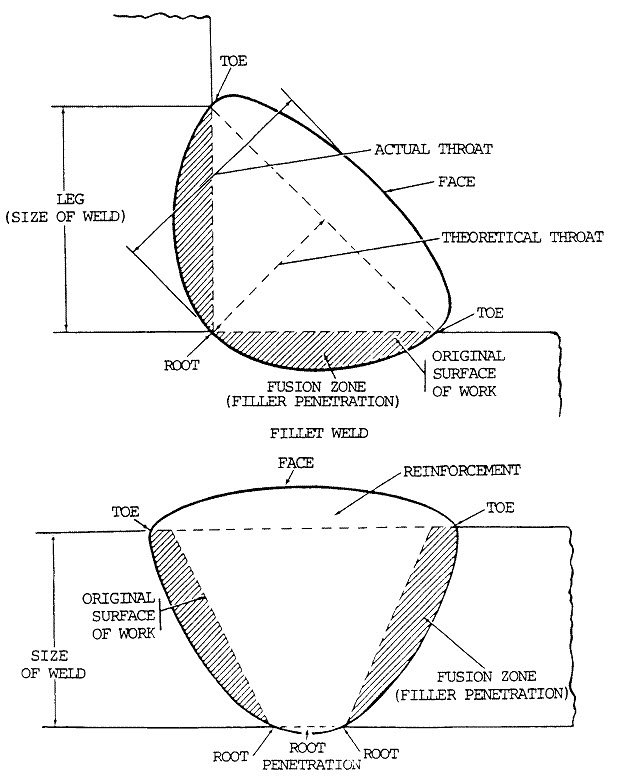

To understand the different parts of a weld use the image above along with the definitions below (the image of a weld above is a cross section view of a fillet weld):

Weld Cross Section Definitions:

Fusion Zone: This is the melted area of the base metal (not the weld metal or filler metal you are welding with). This is where you want your filler metal to penetrate and fuse.

Fillet Weld Leg: The length of fillet weld 'leg' is from the 'toe' of the fillet weld to the joint root. Every fillet weld has 2 legs.

Weld Root: As you can see in the diagram of a weld above, the root of a weld is where the bottom or underside of a weld crosses the surface of the base metal.

Fillet Weld Throat: When you discuss the throat of a weld there are two to consider: 1) theoretical weld throat 2) actual weld throat.

The Theoretical throat is where you take the distance of the perpendicular space from the weld root and the longest side of a right angle triangle (the hypotenuse) of the right triangle you can create inside of the a cross section of a fillet weld.

The Actual weld throat is simply where you take the space between fillet weld root all the way to the center of the weld face (the cross section of) and measure it.

Weld Face:

This is the weld that you create on the side of the metal pieces you

are welding using any gas welding or arc welding process.

Weld Toe: This is simply your weld which joins the metal pieces you are welding together (the weld face and the metal).

As you can see from the diagram above, it's the extra weld metal the exceeds the amount of metal you need for the size of the weld.

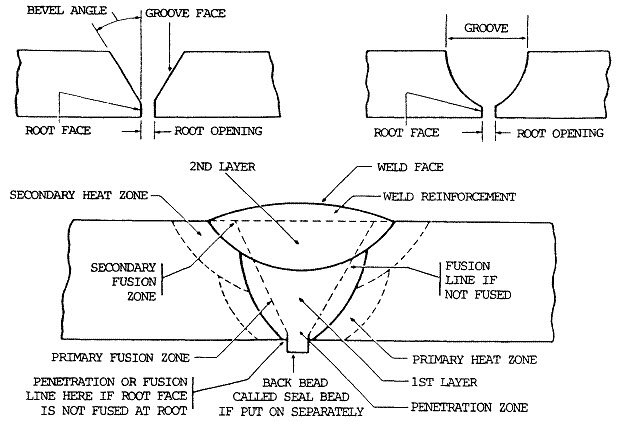

Multipass Welds: Heat Affected Zones In The Parts Of A Weld.

The parts of a weld include what is called a multipass weld. In other words you will find situations where you will need to lay down more than one weld bead to form a junction or weld...

The diagram below shows you the heat affected zones when a butt weld is created using more than one 'pass' (or when you create more than one layer).

Do you see where the area of the weld in the diagram above that shows you the affected area in the first weld layer (first pass)? That is called the primary heat zone.

And the secondary heat zone goes over the primary heat zone (or overlaps the primary heat zone) and it is affected by the second layer or pass.

The heat caused by the secondary zone of the weld allows the primary heat zone to become fused with the base metal and becomes stronger through the process called annealing.

In addition to the annealing affect on the base metal from the second and primary heat zones, the filler metal you deposited in the first pass (your weld) is actually improved from the heat from the second pass or layer.

Related Article:

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: