Gas Welding Explanation and Tutorials!

Gas welding is another broad term (like Arc welding) that describes a process or welding that uses gas to heat your metal for welding as well as your rod or filler metal. However, filler metal is not always needed or used.

Another common term used for this process is oxy fuel welding. What's the most popular way to weld with gas? Answer: Oxy Acetylene welding.

Gas welding basically is gas used as the fuel, and then it's mixed with oxygen, or sometimes it's mixed with air and you use this combination to create the flame which will be hot enough to melt your metal.

As described in the cutting torch article, the mixture of oxygen and the gas are mixed in the welding torch or cutting torch tip, not the body of the torch assembly.

The welding torch (which is usually detachable from the torch base assembly and can be replaced with the cutting torch attachment and vice-versa) gives you the ability to regulate the the flame and therefore the heat you apply to your metal and rod (filler metal).

Get The Entire Aluminum Welding DVD Here.

As I explained above, Oxy Acetylene was the common gas used for

oxyfuel welding. However, another was introduced, and it's called MAPP

(see below).

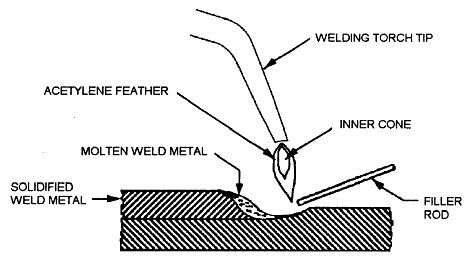

The main purpose of the welding torch flame is

to create a highly focused flame that has the required heat to melt

metal and therefore create a pool of molten metal.

The torch flame also protects the pool of molten metal from atmosphere contaminants as you weld.

Gases

which are not good for gas welding are natural gas, butane, and

propane. Although many people do use propane for their cutting torch

since it does not cost as much as acetylene.

The reason that

these gases are not good for gas welding are due to the fact that the

heat from the flame is not high enough to for a highly focused welding

procedure. It can also cause oxidation during welding, and oxidation is

the enemy of welders.

Get The Entire Oxy Acetylene Welding DVD Here (Highly Recommended).

Here Are The Common Gas Welding Processes:

Pressure Gas Welding: This is a welding process that is not used very often because the heat is not as high as the other processes, but is commonly used for welding lead.

It's a process where the a combination of

pressure and flames are spread across the surfaces to be welded together

all at the same time. So you use both pressure and heat to create the

weld. The gas used is usually Acetylene, and filler metal is not used.

Oxy Hydrogen Welding: When hydrogen and oxygen combusts heat is produced in this welding process.

Much like other welding processes, you will not use any pressure and filler metal is used, if necessary.

The

reason this process is not as popular is because the flare

has no color. And if you don't have color in your flame it's hard to

regulate and adjust the hydrogen and oxygen.

If you need to weld metal with that requires low temperature then this may be something to look into.

Air

Acetylene Welding: If you will be doing any soldering or brazing copper

pipe this is may be a good choice. To create the weld, heat is created

as a result of air and acetylene combustion. You will not use any

pressure, and as usual, you will use filler metal as needed or not at

all depending on the situation.

Oxy Acetylene Welding: This is a

very popular way to gas weld because it produces a lot of heat as a

result of acetylene and oxygen combustion, and it's relatively easy to

regulate. Pressure and rod (filler metal) is used as needed depending on

the project.

MAPP Gas Welding: MAPP gas is gas that is

stabilized and is a mix of of methylacetylene (propyne) and propadiene.

This gas is trademarked by the Linde Group. With a MAPP gas kit

you will usually see the standard gauges (for acetylene), and standard

tips and torches.

With MAPP you will get a cone (the flare) that is up to two times longer than acetylene which may make it a good choice for brazing.

I have no opinion on it. Let me know your thoughts on this or any other welding procedure. Oxy Acetylene is the most common method and I have the most knowledge in it (which isn't all the immense).

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: