AC vs DC Welding!

AC vs DC welding is a widely debated top because ac and dc current options are used in all manner of applications. But you tend to find that only one current type is used. In welding there is a difference because you can have both AC welding and DC welding options.

The choice of AC vs DC welding causes a number of questions to be raised. These questions include people asking what the differences are and also professional and hobby welders across the globe debate on which of the two is the better option for their welding needs.

To help you understand what AC vs DC currents are and what the pros and cons of each are we have compiled the information below. Hopefully this will help you make the right decision in choosing the right current type for your welding needs.

What is AC Welding?

AC welding is where the welder uses an AC current for its supply. An AC current means an alternating current, the term alternating means it's not linear in its supply.

Typically AC currents are what you would expect to see from your electrical outlets in your home or business premises. The AC current when supplied does not move in a straight line, essentially it changes direction at a 60 hertz frequency.

Older welders will only carry AC currents because this is what most of the worlds electrical grids use. An AC current is cheaper and easier to create.

Pros of AC Welding:

AC welding is the preferred method for TIG welding aluminum because the current supports the requirements of welding at a higher temperature.

If you are in an industrial setting where you are in the ship building industry, for example, then AC welding may be preferable. This is because AC welding does not suffer with arc blow to the extent of DC welding.

AC welders are cheaper to produce and because of this they are cheaper to buy.

AC vs DC: The Cons of AC Welding.

As the flow of the current continually moves back and forth at around 120 times a second the arc struggles to be maintained at certain stages of welding and requires being struck again.

The AC weld is not as smooth as a DC weld because of the continuous change in directional flow of the current.

You are more likely to have spatter from the welding process due to the above mention of a less smooth weld.

What is DC Welding?

DC welding is where the welder uses a DC current for its supply. A DC current means the current travels in one direction on a linear setting.

DC currents are not supplied by electrical grids so DC units need an internal transformer to change the current from AC to DC for use; this is evident in its use in welders.

Pros of DC Welding:

You will gain a smoother weld because of the constant and linear direction of the current.

The arc will be more stable and easier to handle using a DC welder and the spatter from the weld will be less because of this.

If you are stick welding a DC welder can use both AC and DC rods while an AC welder can only use AC rods.

AC vs DC: The Cons of DC Welding.

There is a greater potential for arc blow using a DC welder.

The DC welder can sometimes be more expensive because of the additional transformer required to alter the incoming current from AC to DC for use.

DC welding is not ideal for TIG welding aluminum because the current is not the right level to produce the intensity required for this welding type.

AC vs DC Welding and Choosing A Welder:

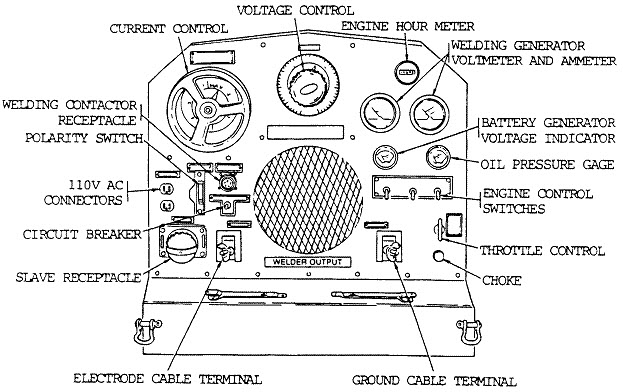

In today's market a lot of the slightly more expensive welders carry the option of having both AC and DC currents with a simple switch between the two.

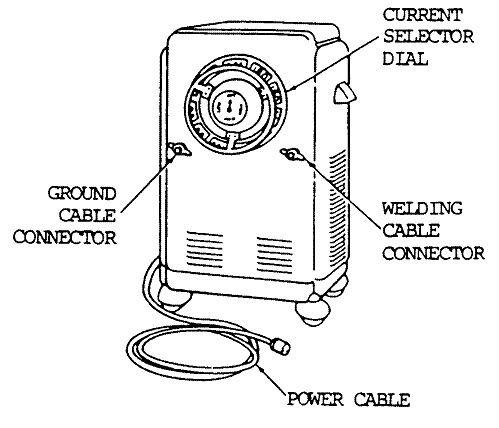

If you don't have the ability to switch between the two current types you will most likely find that the cheaper welders use the AC current as the welder does not need additional components to change the current. Because of this you may not have a choice on the current to use if you have a lower budget.

If you have a little extra cash then you can purchase a DC welder. A DC welder will give you a smoother weld and a more stable arc but there is an additional cost to this that you may feel doesn't warrant the outcome of the weld.

When it comes to AC vs DC welding, there are pros and cons for both. But generally both professional and hobby welders opt for a DC welder where the choice is available to them just for the smoother weld. This being said there are still times where an AC welder is more suitable as mentioned.

What's Your Take On AC DC?

Share your thoughts on AC vs DC welding and welders...

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: