Basic Joint Types and Weldments:

Before I show you the joint types, lets discuss what a weldment is because this will help you put all this welding stuff together a bit better, I feel.

A weldment is basically a bunch

of parts that are welded together. So if you have a ‘weldment’ you are referring

to a weld that is placed where the different bits of metal join together; the

joint.

So when you put two parts together and weld them, you have created a weldment.

And a weldment can be any number of types of

metal. For example a weldment could be in pipe, sheet metal, castings, etc.

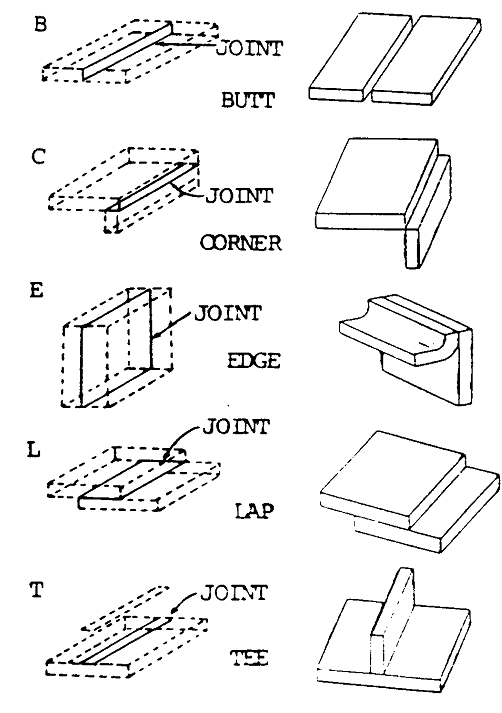

Here Are 5 Types Of Joints:

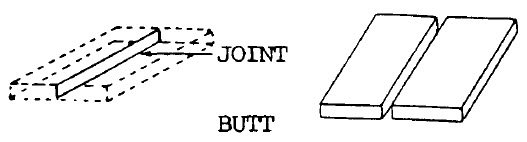

B = Butt Joint:

A butt joint is when 2 pieces of metal are basically in the same 'plane' and need to be 'joined'.

Butt Joint Types In Light Sections:

Butt Joint Types In Heavy Sections:

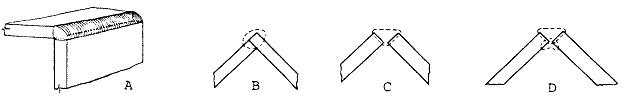

C = Corner Joint:

Corner joints are basically where metal pieces are at usually about 90 degrees. In other words, in right angles.

E = Edge Joint:

Edge joints are just as they sound...it's where 2 metal pieces (or more) are parallel to one another, forming an edge.

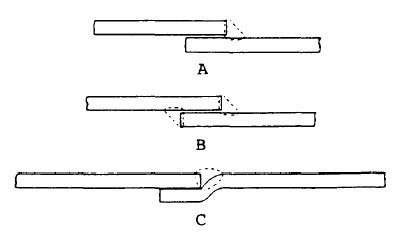

L = Lap Joint:

Lap joint types are simply where metal pieces overlap one another.

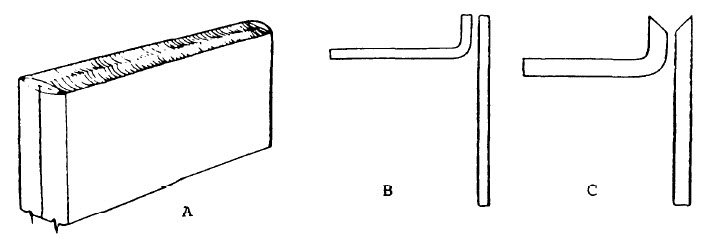

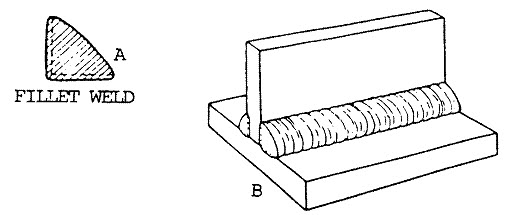

T = Tee Joint:

T joints are again just as they sound. They are metal pieces that come to together to form a T. In other words, the metal parts form a 90 degree angle (a right angle), but they are not on the edge of the one of the metal pieces.

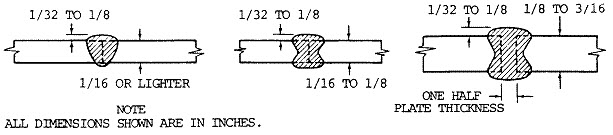

All Welding Procedures Are Not The Same:

You must join together the different joint types with the proper welding procedure and join all the different parts together in order to create your weldment. But the welding process is not always the same for the various joint types.

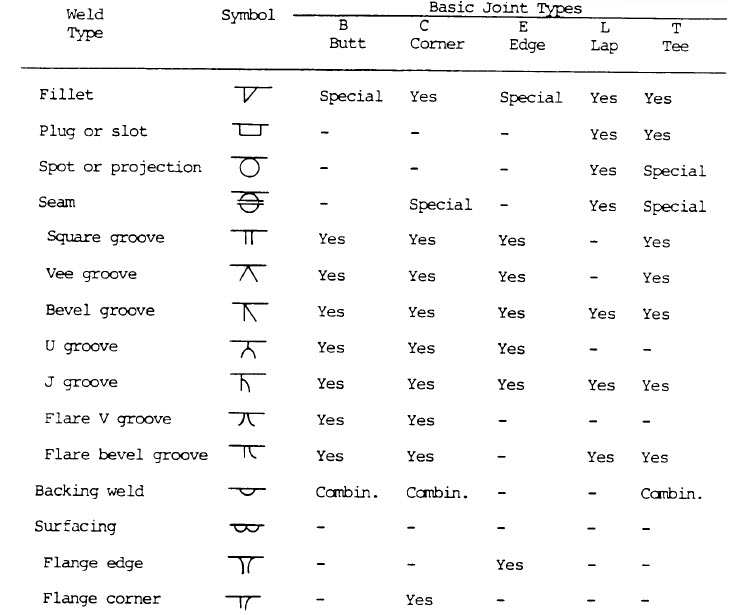

Here are the various welding procedures that can be applied to the different joint types:

Weld Joint Classification:

Basically a joint is created in order to handle spread or transfer stress across the different parts and joints of your weldment.

Since the stresses or loads are going to be put on the various parts of your weldment it is important to create the proper joint to handle them.

This is particularly important for products you will create where lives depend on your welds.

Weld joints have to different types of classification:

- full penetration joints.

- partial penetration joints.

A weld joint classified as full penetration basically has the weld go through the whole cross-section of the joint.

A weld joint classified as partial penetration means that the weld metal did not go all the way through your joint.

This is where ratings of welds comes to play. It’s very simple: a weld with 50% penetration (or partial penetration) means that the weld went through the joint half way (50%).

Strength Of Your Weld:

You might think that the stronger the weld the larger the weld would be. But that is not true. It also depends on the type of of metal you use to weld with. For example, mild steel is a strong metal.

Preparation:

You’ll probably spend more time preparing metal

that you will actually welding it because if there is any dirt, paint,

scale or other foreign material you won’t be able to get a good clean

weld accomplished.

Options for preparing your material

include grinding it down or using specific types of solvent to clean it.

The surface of your joint should be free of any gouges or nicks because

they potentially could cause a problem as you weld. Read More About How To Prepare Metal For Welding Here.

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: