Welding Processes For The Average Welder!

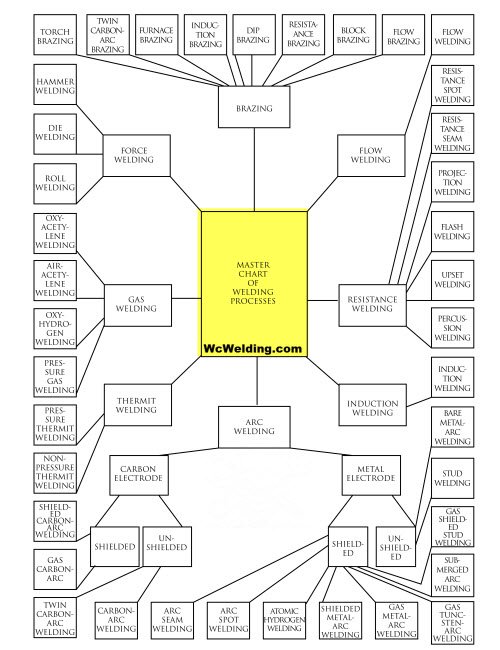

There are many welding processes and therefore there are ways to weld different types of metal (just look at the chart below). But for the average welder you are not going to need to know about most of them.

The average at home welder or small shop fabricator will usually be using one of 4 different types of welding:

- MIG (Wire Feed).

- Flux Core Welding.

- ARC (Stick).

- TIG (More Advanced).

MIG and Flux core are wire feed welding processes and they could be classified under that term but they are different and that will be covered shortly.

But don't let that list keep you from also using other processes like Oxy Acetylene welding because is commonly used but requires more skill. Oxy Acetylene is a Gas welding process.

Wire feed welding is the most common form of welding for the hobbyist, and as I mentioned MIG welding and Flux Core welding is included here.

Each welding process has it's pro's and cons and therefore as you weld projects you may find that one is better or needed more than the other.

For example, you are not going to weld metal that is rusty with MIG. You must prepare your metal. But if you have to weld something with some rust on it you can with a stick welder because it will basically burn right through it.

Also, you can't weld panel or sheet metal well with a stick welder. So if you are working on a car body panel for example, you can use MIG (with a few tricks), TIG, or Oxy Acetylene.

Here is a master chart for all of the welding processes you may come across:

The chart does not include soldering.

4 Welding Processes Explained:

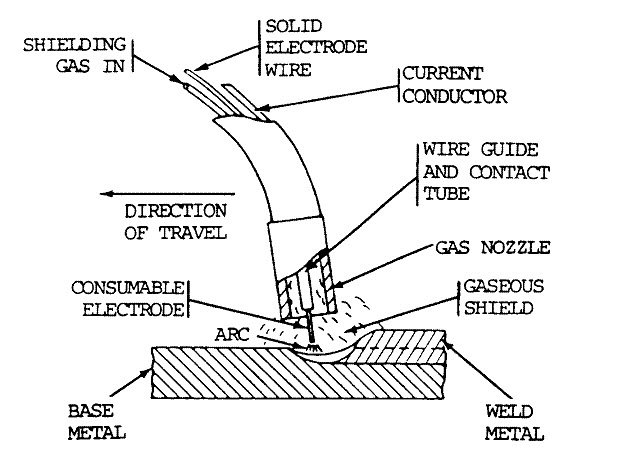

MIG: MIG stands for Gas Metal Arc Welding. It's also known as Gas Metal Arc Welding (GMAW). The way it basically works is that you heat the metals with an arc that is between an electrode (which is the filler metal and is also known as a consumable), and the metal piece you are working on.

In addition you will use a gas, known as a shielding gas, to 'shield' the following from oxygen and other potential atmospheric contaniments that ruin or weaken your weld:

- Arc

- Electrode

- Puddle: the molten metal

The gas you use is completely separate from your welding machine, but it connects to your welding gun.

Your electrode is the wire which comes on a spool, is installed in your welding machine, and the machine automatically feeds the wire through to your welding gun. The wire is your filler metal that is heated along with your metal piece and becomes the weld.

Flux Core Arc Welding: this welding processes is basically MIG welding without the gas. Or you could look at it as stick welding but instead of a stick you have a gun that feeds the wire, and the wire is raplacing the 'stick'. Read this for detailed information on Flux Core.

ARC (Stick) Welding: Stick welding is also called Shielded Metal Arc welding (SMAW).

The 'stick' part comes into play because the electode you will use to create an arc as well as produce the filler metal and therefore the weld, looks like a stick.

So the way this works in a nutshell is that you create an arc between your 'stick', which is CONSUMABLE, and your metal:

The 'stick' or electrode is covered with a material that helps to keep your arc stable, and shields your arc from air. In addition the stick also has the actual filler metal that creates the weld and it also creates a slag which helps to protect the weld. It's pretty amazing what an electrode can do.

The shielding that is created comes from the electrode as it is 'consumed' as you weld.

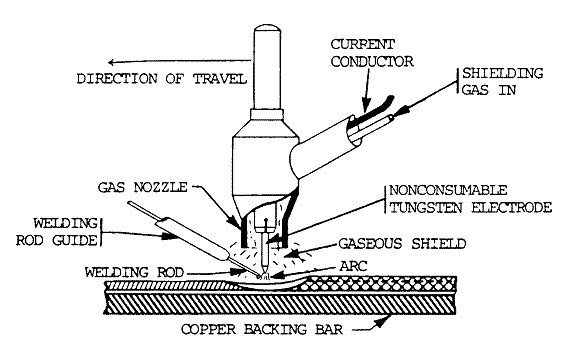

TIG: TIG welding is not for the novice welder who just wants to hobby weld or fix a few things around the house because it requires more expensive equipment and you have to practice it to get good at it.

Conversely, MIG and Flux Core are the very easiest and excellent welding processes for all types of projects. ARC/Stick welding is also good very many projects as well but it's a bit harder than MIG and FLUX.

TIG welding is also know as Gas Tungsten Arc Welding (GTAW).

The way this process works is that an arc is made between an electrode which is NON CONSUMABLE, and the metal you are working on. Similarly to MIG welding you will use a shielding gas to shield your electrode and weld (or puddle) from contaminants in the air...

You will use a filler metal but it is not always needed to create a weld because the arc actually fuses your metal together. Filler metal may be needed, and is often needed depending on what you are working on.

TIG welding is a very versatile process and once you get good at it you will prefer it over other methods. Read this guide for more tips and information on this welding welding process.

Is ARC Welding Really Stick Welding?

Arc welding is a very broad term used to describe a many types of welding processes. It is simply the creation of a weld that joins metals together. The weld is created when an arc is struck and heat is created (extreme heat) between the electrode and your metal.

To make things a little more confusing (but I hope I explained the differences above well enough or you clicked through to more detailed explanations in each welding process description), an electrode can be either CONSUMABLE or NON CONSUMABLE.

- A consumable electrode is either in wire or rod (stick) form.

- A non consumable electrode is either carbon or tungsten (TIG uses a Tungsten electrode) and this non consumable is responsible for maintianing hte arc and carrying the current (which is between the welding gun tip where the electrode is and your metal you are welding). And when you use a non consumable electrode you will use another filler metal in the form of a rod as needed for your weld.

But some welding processes require consumable filler metal to create a weld, and others can actually weld without filler metal (in certain cases). And yet other types of welding require you to push or pull your weld and requires pressure, while others require no pressure at all (like stick welding).

The interesting part of a consumable stick (electrode), and as I described above, is that it has a special coating that accomplishes several things at once (and they look like long incense sticks):

- It is filler material (metal weld for the joint).

- It covers your weld with slag (not always) which helps protect your weld.

It is a conductor: it conducts the electric current and maintains the arc.

So Arc welding is a general term describing many different types of welding processes, but it is commonly referred to and associated with stick welding...

Why that is I am not 100% certain but it organically came to this over time. Let me know if you know the answer. I'm just a welder not a historian :-)

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: