Welding and Eye Protection!

Eye protection when welding or cutting is absolutely the most important thing you need to take care of before you weld, amongst other safety precautions.

And that includes other people who are in the vicinity of your welding and cutting projects.

The reason you want to protect your eyes is because you or your associates are suceptable to glare from welding, sparts, flashes, and hot metal - super hot!

If you weld or cut without eye protection you will get major eye damage. And if a piece of hot metal or a spark hits your eyes or your bare skin you are in for a problem.

Arc welding creates artificial UV rays that will damage your cornea. It happens slowly but surely. It's called flash burn. When you talk with an old or retired welder he can tell you stories about guys who lost an eye or are partially blind because he didn't have or use proper eye protection.

By the way, the reason you see welders wearing welding helmets all the time is because they protect their eyes AND their face and neck from UV rays and stray fragments of metal.

- Image

A below shows you what are called Flash goggles. It's an old school way

of protecting your eyes during welding and cutting. They are to be used

in addition to the welding helmet. So you flip up your welding helmet

lens so that you can perform other work without damaging your eyes (like

cutting).

- Image B shows another old school way of protecting your eyes, except these eye-cup type goggles are used in gas cutting and welding procedures. They should have a lens that filters out harmful rays from gas welding (which is infrared). DO NOT use gas welding or cutting goggles for eye protection from arc welding rays!

Types Of Eye Protection For Welding and Cutting:

Arc Welding Helmet!

When you are arc welding or cutting you have to have a helmet that is fitted with the proper type of lens.

The welding helmets in Image C and D below have flip up windows that are actually lenses that filter out UV rays from welding and cutting.

- The first helmet (C) has a smaller lens. It is 2" x 4.25". This is a smaller opening.

- The second helmet (D) has bigger lens. It measures 4.5" x 5.25". A bigger lens is like having a bigger window to look out of and it's very handy because you can see more. And when you see more you can do more and be safer. However, they usually do not flip up because they are so big, and that's why the small window is a popular choice, because being able to flip up provides you with more air and you can see your work clearer.

However, it's important that you wear the flash type goggles shown above underneath in case there's another welder in the vicinity so that you aren't affected by their arc welding flashes.

As I mentioned above the flash goggles will also keep your eyes safe from bits of metal and slag.

Good quality helmets and some goggles have removable lenses which include both a filter lens and a clear protective lens. There is a protective lens in front of your filter lens which protects it from sparks and spatter, which will damage your filter lens.

Side Bar: Steve Bleile uses a protective lens in front and in back of his filter lens.

The filter lenses come in different shades which are denoted by numbers. For a lighter shade lens there is a lower number, and for a darker lens the number is higher. You choose the proper shading depending upon the welding job.

However, if you have auto-darkening welding helmet you don't need to place different lenses for the type of operation. You just set the number and it adjusts automatically.

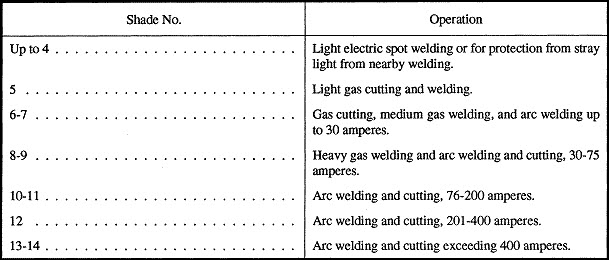

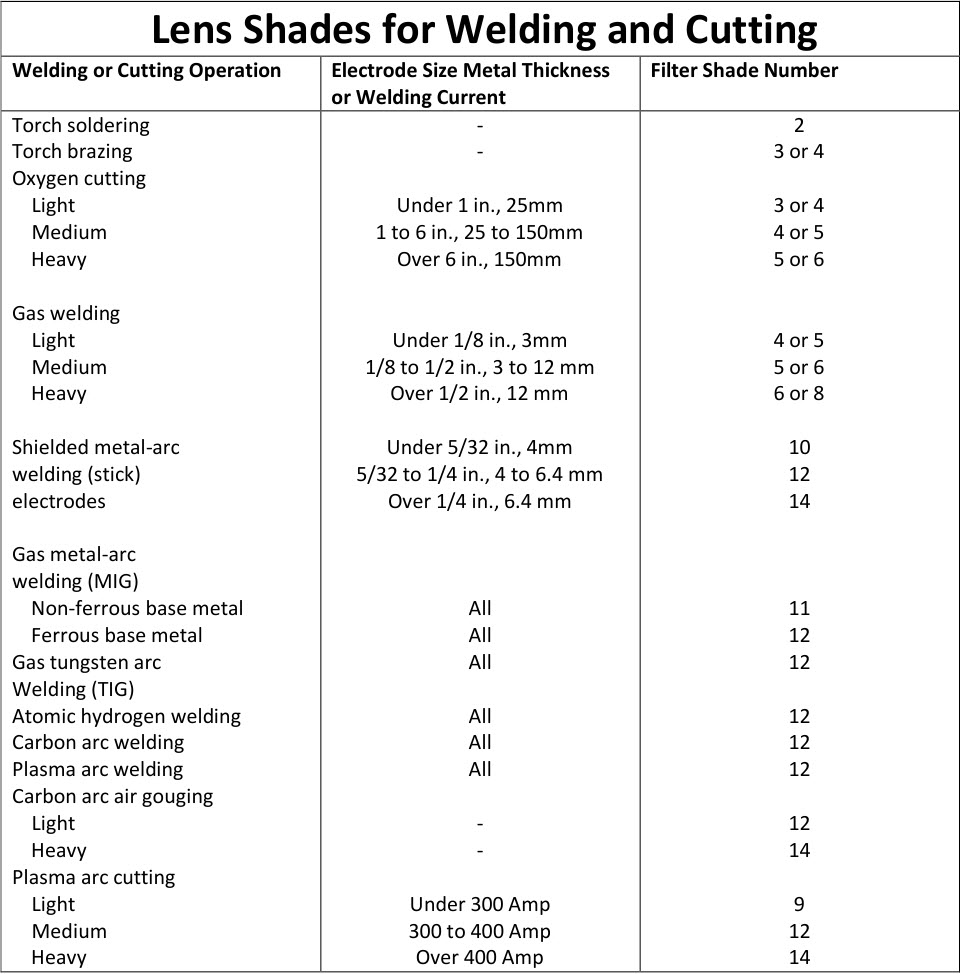

Lens Shade Numbers For Different Welding Projects:

Click this welding helmet lens chart image for a larger view.

More Advanced Lens Shade Chart For Welding and Cutting:

Two Reasons For A Filter Lens:

- You need a filter lens to lower the intensity of the light so that it eliminates glare fro welding and so you can see the weld puddle. You can't weld if you can see the puddle or the area you are welding.

- Damage from UV rays. If you don't have a lens that filters out UV radiation from arc welding you will get flash burn or worse.

Welding Helmet Tip:

If you are not sure about the lens shade for your welding job try this; fit the lens inside our helmet and then look at a fairly bright light bulb (that is turned on).

Can you see the outline of the light bulb? If you can then you probably need a darker lens. So then try it again with a darken lens. If you cannot see the outline of the light bulb then it is probably the right one.

Don't do this test in your home or office but in the area you are going to be welding in because the lighting is different.

If you are welding outside you can try looking at a bright object in the area that is reflecting the sun.

Use the chart above or read the manual that came with your welding helmet.

ATTENTION: Never weld or cut without proper eye protection. And never look at an arc even for a second! You can get major eye damage permanently. It's one of the most common welding accidents in the industry.

Related Articles:

Copyright WcWelding.com All Rights Reserved.

Welding Plans:

New! Welding Table

New! Log Splitter

Top Projects: